How construction debris detection from a drone can reduce inspection cost

Summary

We developed a drone-based application that was able to detect and report 25 different types of construction debris for a city municipality. The solution allowed to automatize the construction site inspection process while reducing human involvement and average inspection costs considerably. According to our customer estimates, the system saved 320 man-hours per month and reduced average inspection costs by 40%.

Challenge

A city municipality requested a solution that allowed them to fully automate construction site compliance monitoring and detect abandoned construction debris such as bricks, cement blocks, sand heaps, metal and wooden sticks, etc. It was crucial to have an automated solution, like drone computer vision, that would minimize human involvement in the inspection process thus reducing labor costs as well as the time required for an inspection.

Solution by AI Superior

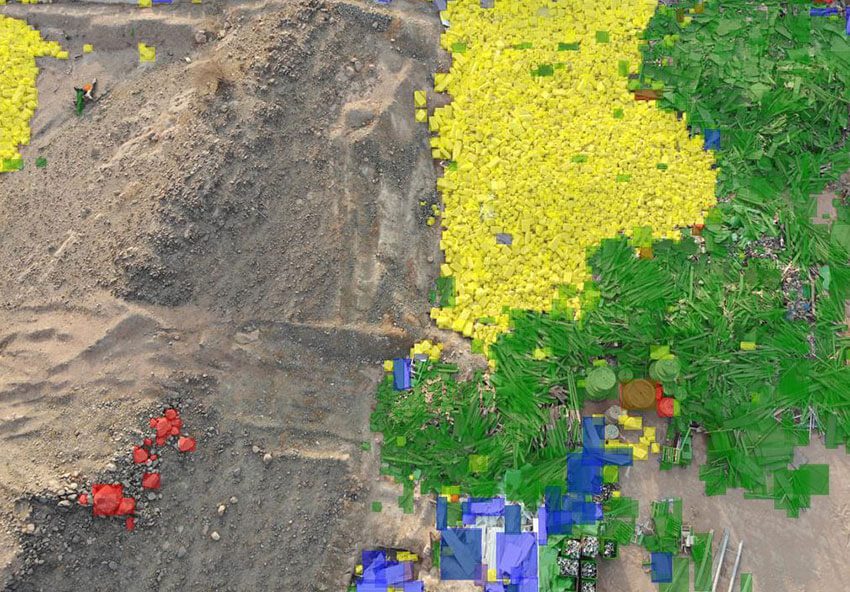

We applied our proprietary computer vision technology for object detection, classification, and segmentation to detect 25 different classes of construction debris. We built a GIS dashboard to allow selection of a construction site and the visualization of all the debris detected within it.

Additionally, for every detected object, the system provided an estimated size (area) of construction debris (for a single object and clusters of objects of the same type) and the number of detected objects. The application provided insights, while employing a GIS dashboard and exposed APIs to query detection results – this allowed the solution to be integrated to practically any other system.

The picture shows the result of the construction debris detection from a drone. The different objects are dyed in different colors.

Outcome and Implications

The solution was adopted by multiple city municipalities demonstrating its operational and economical effectiveness. Furthermore, according to our customer estimates, the system saved 320 man-hours per month and reduced average inspection costs by 40%